Laser Cutting

Laser cutters use high-power laser systems which allow for precise and fast cutting of materials. DBE has 12 laser cutters in total; 2 are technician-operated large format laser cutters, and 10 small-format laser cutters that students can operated once trained.

Prepare your files for laser cutting using the information and guides below.

Equipment Specifications

| Type | Quantity | Dimensions | Materials | Location |

|---|---|---|---|---|

| Trotec SP500 | 1 | 1245 mm x 710 mm | Strawboard (1 and 2mm), plywood (3 and 6mm) | 418 Makerspace |

| Darkly Labs Emblaser 2 | 10 | 500mm x 300mm | Strawboard (1 and 2mm), plywood (3mm) | 418 Makerspace |

| Trotec Speedy 400 Flexx | 1 | 1000 x 610mm | Strawboard, plywood, acrylic, mylar, fabrics, and other materials. | 202 Digital Modelling |

Emblaser 2 This equipment can be operated by students who have completed a laser cutting badge. Students must watch the equipment for the entire process.

Materials

- Polycarbonate

- PVC (vinyl)

- Anything containing chlorine

- Metals

- MDF

- Any materials without a Safety Data Sheet (SDS/MSDS)

Materials that can be cut and/or engraved

Both the Makerspace and Digital Modelling Workshop stock plywood and strawboard for laser cutting.

The Makerspace laser cutters cut supplied materials only:

- Plywood 3mm and 6mm thick, up to 1200 x 600mm in size

- Strawboard 1mm and 2mm thick, up to 900 x 600mm in size

You cannot bring in other materials to cut on the Makerspace laser cutters.

The Trotec Speedy 400 Flexx in the Digital Modelling Workshop can cut a wider range of materials, including:

- Cast acrylic

- Wood (thin veneers, plywood, balsa)

- Fabric (natural or acrylic based)

- Leather

- Card and paper

- Polyethylene

- Acetate

And can engrave (but not cut) some others, such as:

- Glass and ceramics

- Solid wood

Material costs

Some units require you to a pay a consumables fee, which covers the costs of some or all of your materials. If your material costs are not covered by a consumables fee, you will need to pay for supplied laser cutting materials at cost price.

File Preparation

Vector files Only

- Vector files are the only format the laser cutter will recognise for cutting and vector engraving

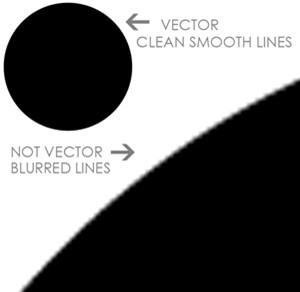

- A vector file is made up of shapes and lines that do not lose resolution or quality when they are scaled; they use mathematical equations to define shapes and lines

- You can create vector files using programs such as Adobe Illustrator, CorelDraw, Rhino 3D, and AutoCAD, as well as free software like Inkscape.

- Vector files need to be created in a vector program - not just imported or pasted.

Line and shape properties

There are slight differences between line colours when preparing files for Trotec (large format) laser cutters and Emblaser (small format) laser cutters. Use the following settings:

Vector Vs Raster

The difference between vector graphics and raster graphics are as follows. Vector graphics use mathematical equations to define shapes and lines, while raster graphics are made up of individual colored pixels arranged in a grid. Therefore, vector graphics can be Infinitely scaled without losing fidelity.

Trotec (SP500 and Speedy 400 Flexx)

Cut: RGB red, hairline thickness

Vector engraving: RGB green, hairline thickness

Raster engraving: RGB black or greyscale; a solid fill engrave should be black fill, while you can use greyscale to create different tonal values or depths

Emblaser 2

Cut: RGB red, hairline thickness

Vector engraving: RGB green, hairline thickness

Solid fill raster engraving: RGB blue, hairline thickness

Tonal value/gradient: Greyscale

File size and format

- Files must be saved in PDF format

- Your PDF must be the size of your material sheet (e.g. 900 x 600mm for strawboard)

- Save each sheet as a separate PDF file

How to set up your files > Software + Templates

AutoCAD

AUTOCAD > FILE SET UP GUIDE > PDF

AUTOCAD > TEMPLATE > TROTEC SP500 > DWG

AUTOCAD > TEMPLATE > EMBLASER2 > DWG

Rhino 3d

RHINO > FILE SET UP GUIDE > PDF

Fusion 360

Fusion 360 laser Cutting Guide